The Relevance of Routine Strapping Machine Service for Smooth and Reliable Packaging Procedures

Routine strapping machine service plays a crucial function in guaranteeing reliable packaging procedures. Ignoring upkeep can bring about unforeseen breakdowns and lowered productivity. By proactively addressing possible issues, organizations can enhance both machine efficiency and product top quality. Comprehending the significance of normal service is basic for maintaining operational performance. Lots of companies overlook this important aspect. What factors should be thought about to develop a reliable maintenance approach?

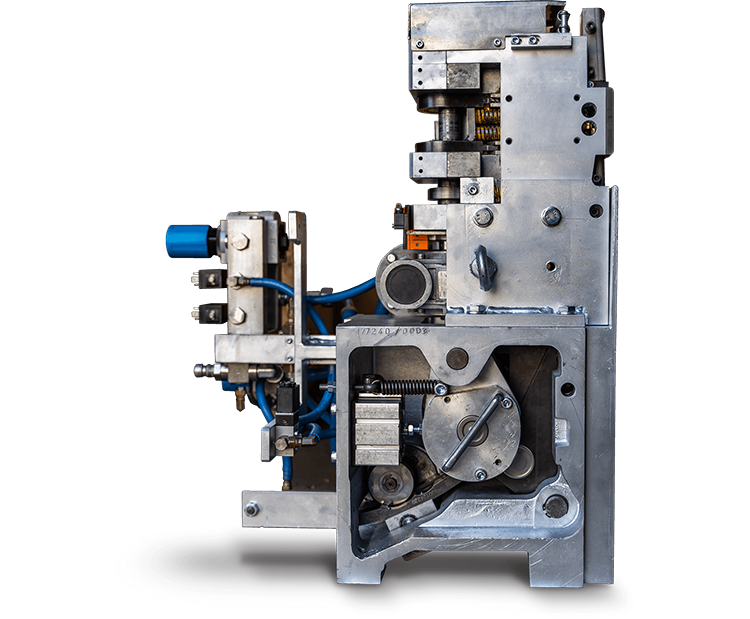

Understanding Strapping Machines and Their Function in Product packaging

Strapping machines might appear like straightforward devices, they play a crucial function in the product packaging market by guaranteeing the protected packing of items. These machines apply plastic or metal straps around plans, giving stability during transportation and storage space. By developing tight, reliable seals, strapping machines aid prevent damages and maintain product stability. Their efficiency adds to much faster packaging processes, allowing businesses to satisfy increasing demand without compromising top quality. In addition, strapping machines can be integrated into automated systems, enhancing process and lessening labor prices. The flexibility of these machines makes them suitable for various sectors, from making to distribution, guaranteeing that products stay intact throughout the supply chain. Inevitably, strapping machines are critical to successful product packaging procedures.

Common Problems Developing From Lack of Maintenance

When strapping machines are not appropriately preserved, numerous typical concerns can develop that prevent their performance and dependability. Regular break downs can happen because of damaged elements, causing costly downtimes and disrupted manufacturing timetables. Furthermore, incorrect tensioning might cause weak seals, endangering bundle stability. Dust and particles build-up can impair machine sensing units and moving parts, triggering irregular procedure and boosted wear. Furthermore, neglected lubrication can result in friction and getting too hot, further harmful inner systems. Operators may likewise deal with difficulties when readjusting setups on improperly maintained machines, leading to inconsistent packaging results - strapping machine service. In general, a lack of maintenance can significantly affect the efficiency and effectiveness of strapping machines, ultimately influencing the entire packaging procedure

Advantages of Normal Strapping Machine Service

Routine strapping machine service provides considerable advantages that add to functional success. By making sure enhanced tools durability and enhanced functional performance, services can decrease the likelihood of unforeseen malfunctions. Inevitably, this aggressive approach decreases downtime threats, promoting a much more reliable production setting.

Boosted Equipment Long Life

Maintaining a strapping machine via routine service considerably adds to its overall long life. Regular inspections and maintenance aid determine deterioration prior to they escalate into substantial problems, therefore prolonging the life of crucial components. By resolving minor faults without delay, operators can stay clear of costly repairs and extensive downtime that can develop from disregard. Additionally, regular servicing assurances that all mechanical parts work effectively, lowering the risk of machine failure during procedures. This proactive approach not just enhances the strapping machine's sturdiness yet also cultivates a more secure working atmosphere. Eventually, buying normal service equates to a much more trustworthy machine that regularly fulfills manufacturing needs, protecting the integrity of the product packaging process for many years to come.

Improved Operational Efficiency

Routine service of strapping machines considerably boosts functional effectiveness by making sure that all parts operate at their best. Regular maintenance decreases the risk of mechanical failures, permitting regular and trustworthy efficiency. Well-maintained machines operate at ideal speeds, maximizing throughput and lowering the time needed for product packaging procedures. This performance not only assists fulfill production targets yet likewise contributes to a smoother workflow, as drivers can count on the equipment without disturbances. In addition, routine servicing determines possible concerns early, permitting corrective activities to be taken prior to they escalate. Because of this, organizations experience structured operations, which can cause increased efficiency and improved total performance in packaging jobs. Routine service is crucial for preserving an efficient product packaging atmosphere.

Decreased Downtime Threats

Effective service routines for strapping machines noticeably lower the dangers of downtime related to unforeseen mechanical failures. Normal maintenance checks aid recognize potential concerns prior to they rise, making certain that machines operate efficiently and dependably. By resolving damage, lubrication demands, and electric parts proactively, services can prevent pricey disruptions in their product packaging processes. Additionally, set up maintenance enhances the life-span of strapping machines, decreasing the regularity of substitutes and linked prices. The decrease in unexpected downtime not only enhances productivity yet also boosts worker spirits, as employees can rely upon equipment that functions perfectly. Ultimately, dedicating to regular service builds a resistant operation, securing against disruptions and allowing firms to fulfill production targets regularly.

Secret Parts to Display During Regimen Service

While performing routine service on a strapping machine, it is vital to monitor numerous vital parts to protect peak efficiency and longevity. The tensioning mechanism needs to be looked for proper operation, ensuring that bands are safely tightened up without creating damages. The sealing device should be examined for damage, as any kind of malfunction can endanger the stability of the packaging. In addition, the feed system calls for focus to ensure constant and smooth band distribution. It is likewise important to analyze electric connections, as damaged or loose wiring can result in operational failings. Lastly, lubrication degrees should be examined to avoid friction-related concerns, advertising reliable machine feature. On a regular basis keeping track of these elements will contribute substantially to the machine's overall integrity.

Creating an Upkeep Schedule

A well-designed upkeep schedule plays a crucial function in making certain the perfect operation of a strapping machine. It ought to include regular assessments, cleansing, and component replacements based upon the maker's referrals. Developing a regularity for these tasks-- such as weekly, monthly, or quarterly-- can assist preemptively address prospective issues. In addition, recording each maintenance task improves responsibility and permits for tracking the machine's performance gradually. Operators should also think about the production quantity and specific functional needs when tailoring the routine. By prioritizing regular service, businesses can reduce downtime, extend the machine's lifespan, and preserve consistent you can try these out product packaging quality. Eventually, a complete maintenance schedule is important for optimizing strapping machine capability and reliability in product packaging procedures.

Picking the Right Service Provider

Just how can one assure the choice of a suitable service providerfor strapping machine maintenance? First, it is vital to research study prospective suppliers thoroughly. Reviewing their experience, market credibility, and experience in strapping machine innovations can provide valuable understandings. Additionally, consumer reviews and reviews often expose the quality of service and integrity.

Next off, consider the company's qualification and training programs, which indicate their dedication to preserving high criteria. It is also important to ask about their reaction times for service calls and the accessibility of spare components.

Last but not least, getting several quotes enables a comparison of rates and service packages, ensuring an educated decision. Eventually, the ideal copyright will boost efficiency and lower downtime in product packaging procedures.

The Long-Term Effect of Consistent Machine Care

Regular machine care greatly affects the longevity and performance of strapping machines, as normal maintenance helps recognize potential concerns prior to they intensify. By implementing a structured service routine, companies can minimize unforeseen downtimes and costly fixings. This proactive method not just guarantees peak operating however likewise improves the quality of packaging, resulting in boosted customer complete satisfaction. Over time, well-kept machines display far better efficiency, causing minimized functional costs see this page and enhanced productivity. Furthermore, a culture of regular care fosters worker confidence in equipment dependability, advertising a smoother process. Inevitably, the long-lasting effect of consistent machine care equates right into substantial savings and an one-upmanship in the packaging industry, making it an indispensable practice for companies seeking lasting growth.

Regularly Asked Concerns

Just how Often Should I Replace Strapping Machine Parts?

Strapping machine parts ought to be replaced every 1,000 to 2,000 hours of procedure, depending upon usage strength. strapping machine service. Regular assessments can aid establish particular demands, making certain peak efficiency and decreasing downtime from devices failure

Can I Carry Out Upkeep on My Own?

Yes, one can carry out upkeep on their own, given they possess the essential skills and understanding. Nonetheless, seeking advice from the supplier's standards is vital to assure proper treatments are followed and security is kept.

What Indicators Indicate I Required Immediate Service?

Signs suggesting the requirement for instant service consist of unusual noises, irregular strapping stress, regular mistake messages, noticeable endure parts, or unexpected closures (strapping machine service). Attending to these issues quickly ensures operational effectiveness and stops additional damage

How Does Weather Affect Strapping Machine Efficiency?

Climate condition can greatly affect strapping machine performance. Extreme temperatures, moisture, and wetness degrees might trigger products to increase or contract, impacting tension and seal integrity, resulting in prospective operational concerns and lowered product packaging performance.

What Is the Ordinary Cost of Regimen Service?

The typical price of regular service for strapping machines typically varies from $150 to $500, relying on the machine's complexity and the provider's competence, ensuring peak performance and long life of the he has a good point tools.

Routine strapping machine service plays an important duty in making certain efficient product packaging operations. Regular service of strapping machines greatly enhances functional performance by ensuring that all elements operate at their best. While doing routine service on a strapping machine, it is vital to keep track of several crucial elements to secure peak efficiency and long life. By prioritizing routine service, services can reduce downtime, prolong the machine's life-span, and maintain constant product packaging top quality. Consistent machine treatment considerably affects the long life and efficiency of strapping machines, as routine maintenance aids identify possible problems prior to they rise.